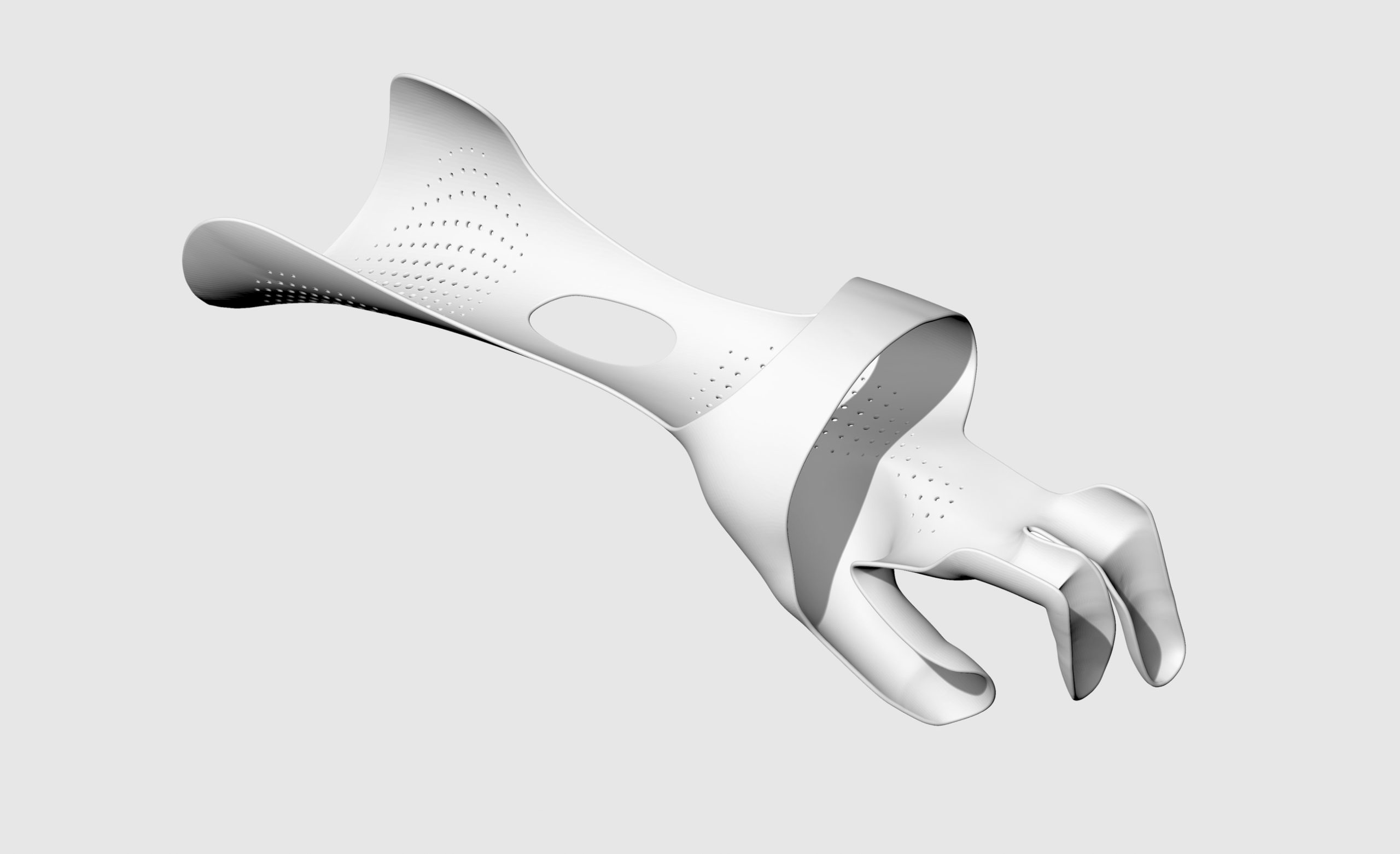

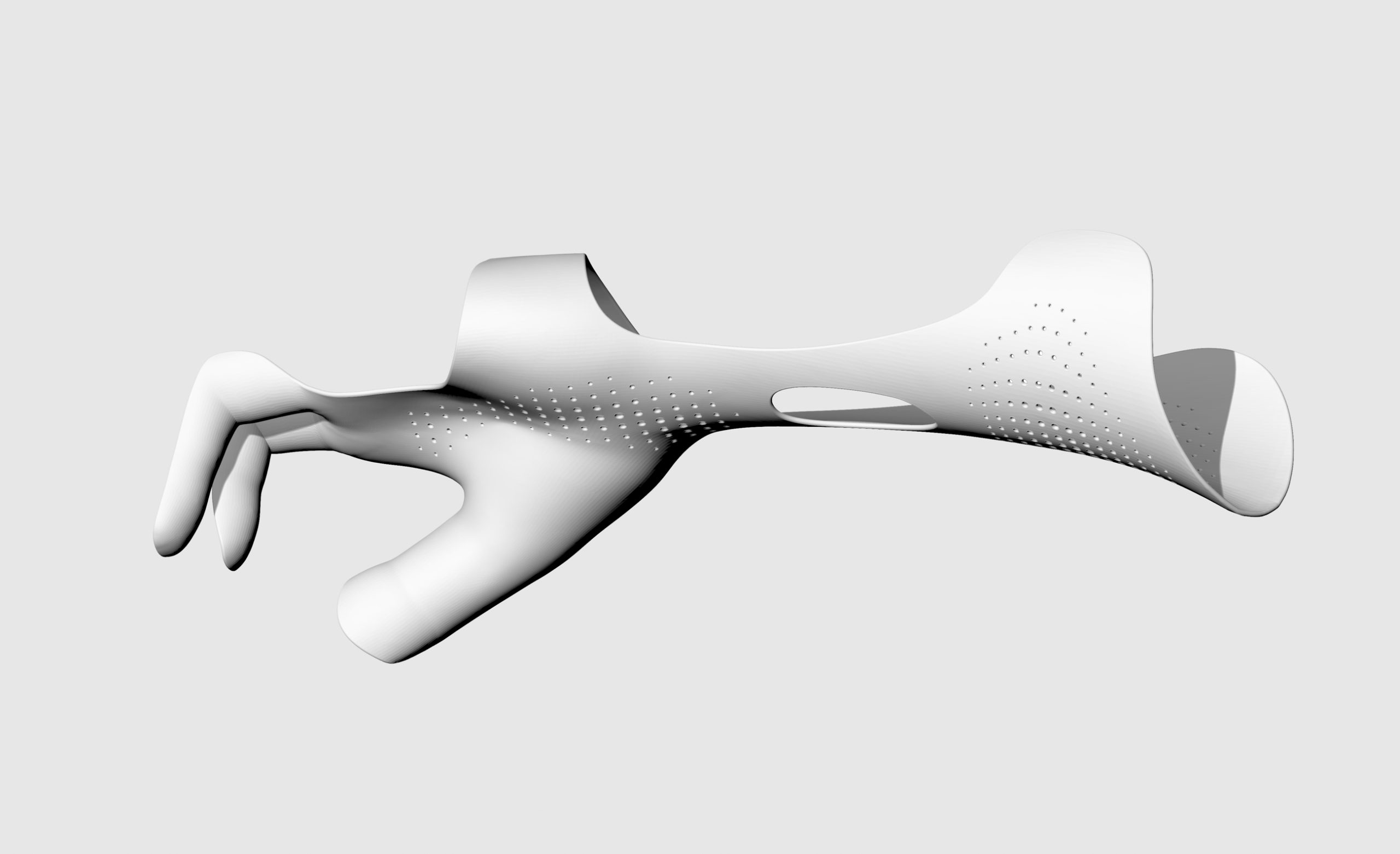

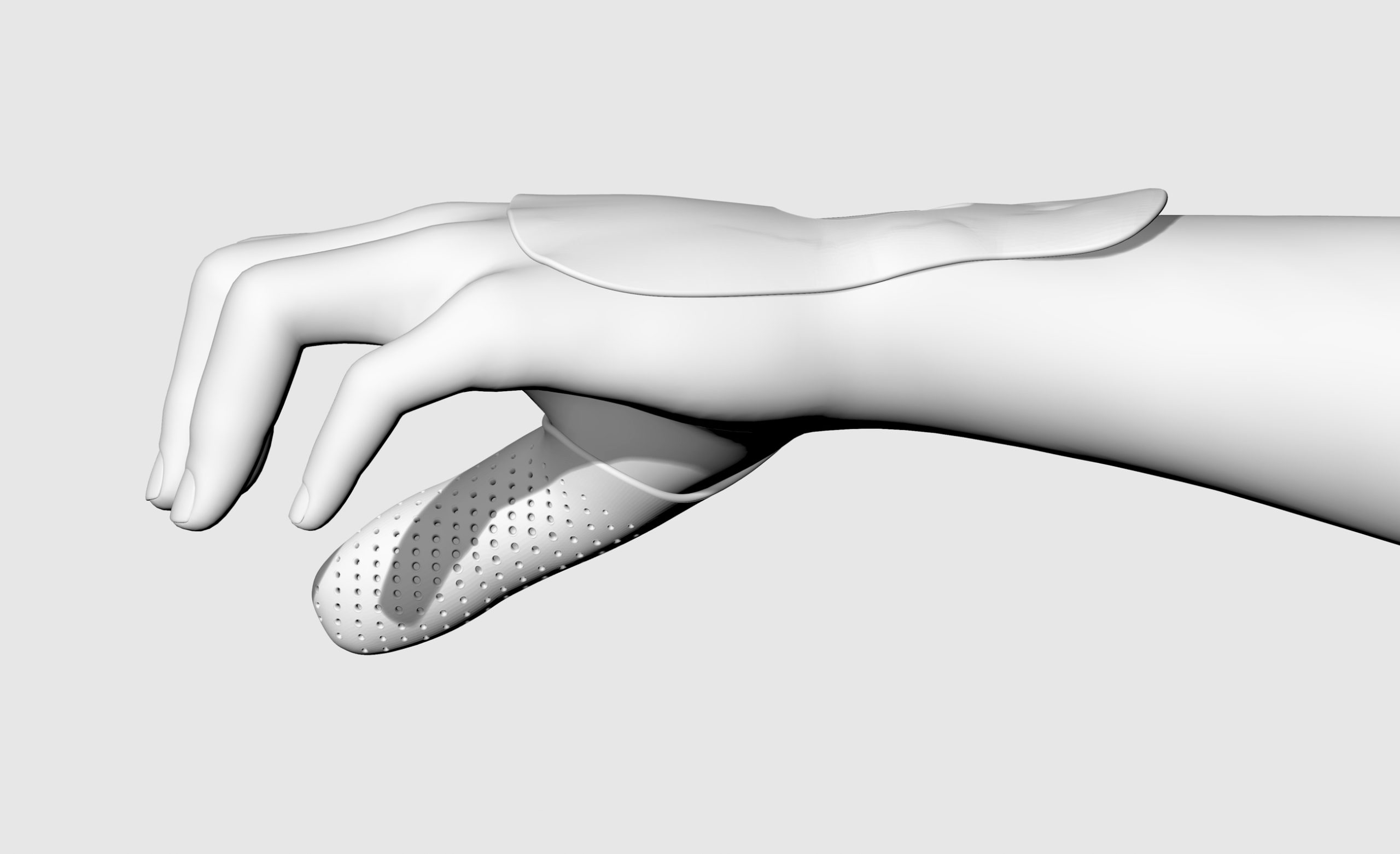

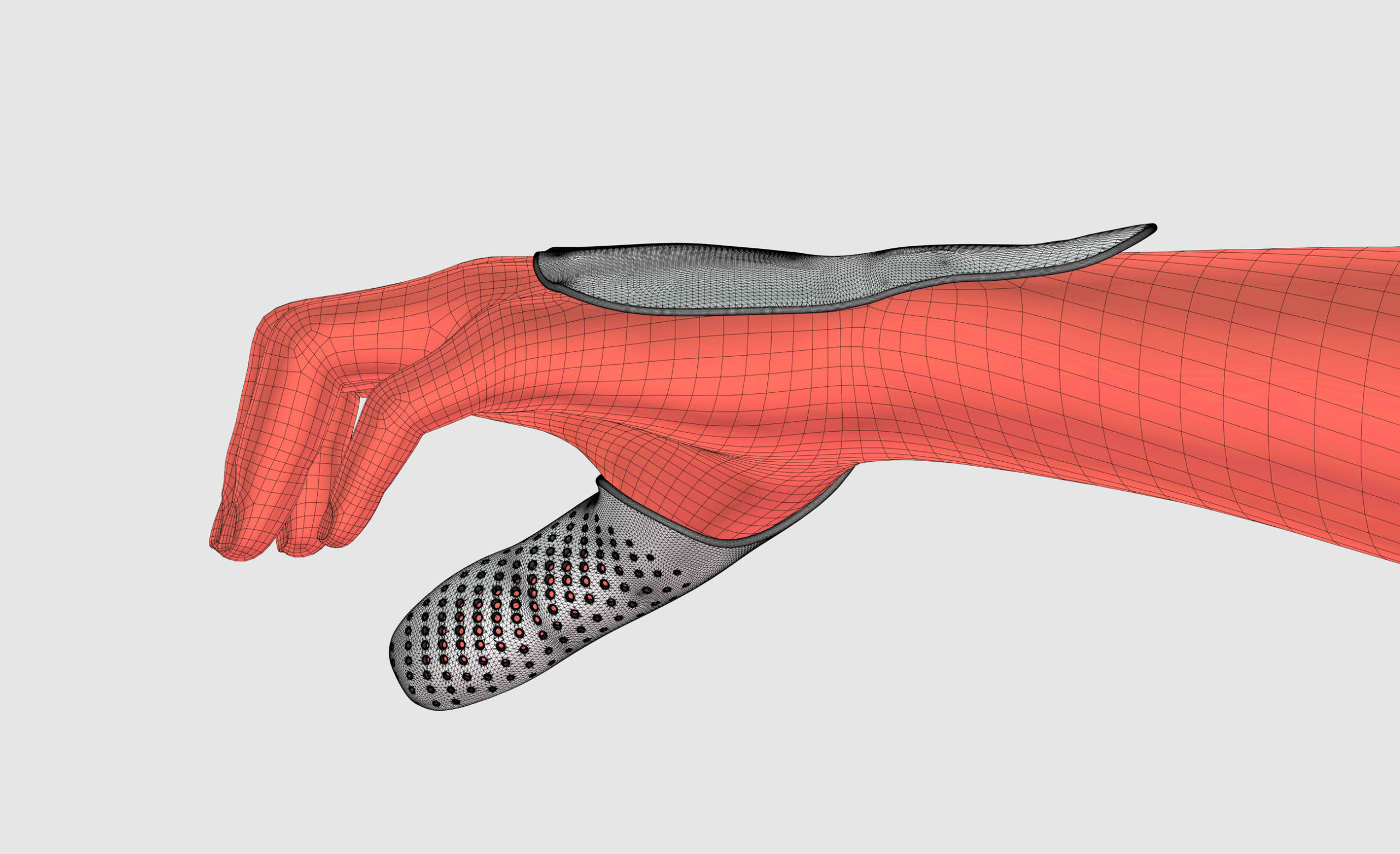

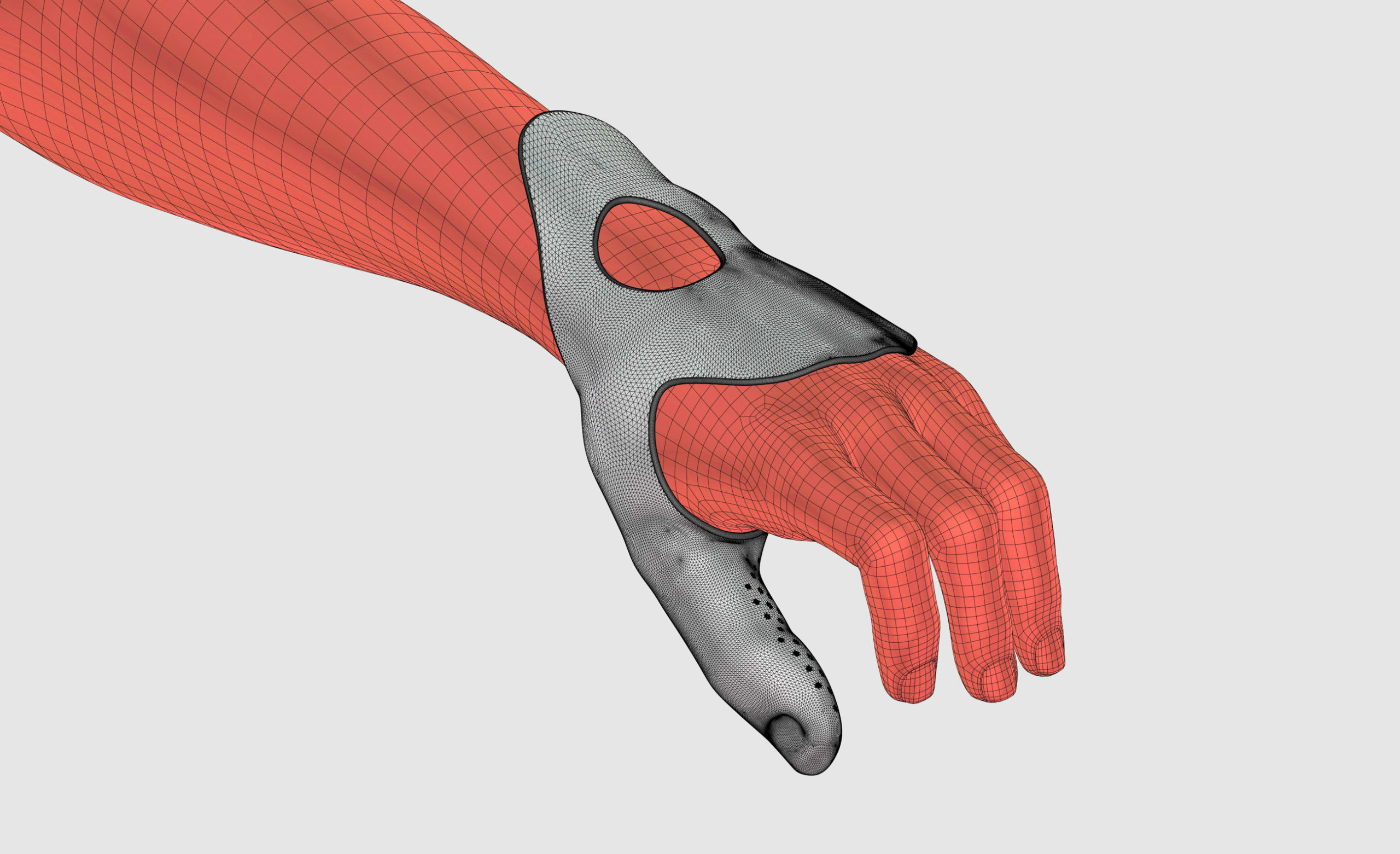

The aim was to develop an automated system to completely relocate the conventional planning and manufacturing process for the creation of hand orthoses into the digital space. This resulted in a parametric system in which the orthopedic surgeon can determine input parameters such as the outer contour, raised edges, wall thicknesses and perforation areas directly in 3D. The algorithm in the background ensures that a digital hand orthosis is generated in real time. In conjunction with the possibilities of additive manufacturing, the human labor required for the entire production cycle of an orthosis can be reduced from around 2 days to less than 20 minutes.